3.5-Ton Compact & Powerful Mini Excavator

1.Yanmar Power Support + Dual Fuel Filtration Protection, Stable and Efficient.

2.Multiple Bucket Adaptation + High-Strength Compact Structure, Comprehensive Working Condition Coverage.

3.Humanized Cab Configuration, Easy and Convenient Operation.

In diverse scenarios such as municipal pipe network renovation, indoor decoration demolition, orchard and agricultural maintenance, and small-scale infrastructure construction, the 3.5-ton mini excavator has become the preferred equipment for numerous construction parties with its core advantages of "small but refined, powerful yet economical". Equipped with high-performance configurations to lay a solid foundation for performance and upgraded operating experience through humanized design, this product fully adapts to narrow-space operations and multi-task switching needs, providing comprehensive guarantee for efficient construction.

1.Yanmar Core Power, Both Powerful and Energy-Saving

Power performance is the core guarantee of construction efficiency. This product is equipped with the renowned Yanmar engine, with a rated power of 22.2 kW, delivering strong and stable power output that can easily handle medium and light workloads such as excavation, crushing, and leveling. Relying on Yanmar's mature electronically controlled direct injection technology, the fuel combustion is more sufficient, improving fuel utilization from the source and achieving a perfect balance between power and energy saving.

2.Dual Fuel Filtration Protection, Precise and Efficient Hydraulics

The equipment is equipped with a complete fuel filtration and storage system, constructing a dual protection line of pre-filter and main filter. It can efficiently remove impurities and moisture in the fuel, effectively avoiding wear risks of precision components, significantly reducing the probability of fault shutdown, and adapting to operating needs in complex fuel quality environments. Combined with the main pump's large flow output of 108 L/min and precise hydraulic control valve, the action response is sensitive and rapid, and the composite operation is smooth. It can not only cope with high-intensity continuous operations but also meet the needs of precise positioning operations, greatly improving the operating efficiency per unit time.

3.Multiple Buckets Optional, One Machine for All Scenarios

Targeting the diverse needs of small-scale construction scenarios, this product accurately matches multiple operating requirements. The standard bucket capacity is 0.13 cubic meters, and at the same time, multiple specifications and shapes of buckets such as standard, narrow, and wide are available. It can be flexibly switched to adapt to different operating scenarios such as municipal trenching, indoor crushing, orchard ditch cleaning, and site leveling, truly realizing "one machine for multiple uses", effectively reducing equipment investment costs and improving comprehensive equipment utilization.

4.High-Strength Compact Structure, Stable Walking on All Terrains

The boom and arm are precision-welded with high-quality steel and adopt a compact structural design. It not only reduces space occupation during operation, perfectly adapting to narrow-site operations but also has ultra-high structural strength and excellent fatigue resistance, which can easily withstand impact loads under complex working conditions. The walking system is equipped with a high-torque output travel motor, providing sufficient power for track movement, and has strong ground adhesion and passability. It can easily cope with various terrains such as farmland, mountainous areas, and flat construction sites, ensuring stable travel and efficient operation throughout the process.

5.Ergonomic Design, No Fatigue After Long-Time Sitting

Considering the needs of long-time operations, the cab adopts a humanized design: equipped with an adjustable ergonomic seat that fits the body shape and disperses pressure; the standard air conditioning system achieves precise temperature control, and the sealed design isolates dust and noise, creating a comfortable operating space and greatly reducing fatigue.

6.Convenient Operation, Easy for Novices to Get Started

A radio is equipped in the cab to relieve the boredom of operation; the operation buttons are reasonably arranged and within easy reach, combined with clear guidelines, allowing novices to quickly familiarize themselves with the operation process, balancing efficiency and safety.

From strong and stable power output to flexible and diverse working condition adaptation, and then to comfortable and convenient operating experience, the 3.5-ton mini excavator has become an ideal choice for small-scale construction scenarios with its all-dimensional core advantages. Whether it is a professional engineering team or an individual construction household, choosing this product can accurately achieve the core demand of "efficient operation and low-cost operation and maintenance", helping each construction task proceed smoothly and be completed successfully.

Product model | SH35 | |

Total weight | kg | 3900 |

Bucket capacity | m³ | 0.13 |

Engine | ||

Engine model | / | 3TNV88 |

Intermittent spray | √ | |

4-stroke | √ | |

Water cooled | / | √ |

No.of cylinders | 3 | |

Rated power | kW/rpm | 22.2/2400 |

Displacement | L | 1.6 |

Oil Capacity | ||

Fuel tank | L | 40 |

Hydraulic tank | L | 40 |

Engine oil | L | 6 |

Hydraulic System | ||

Rated fowof main pump | L/min | 108 |

Pressure-main valve | MPa | 25 |

Pressuretravelsystem | MPa | 25 |

Presure swing system | MPa | 25 |

Pressure pilot system | MPa | 3.9 |

Main Performance | ||

Travel sped (hgh/low | km/h | 4.6/2.6 |

Swing speed | r/min | 10 |

Gradeability | 0 | 35 |

Ground pressure | kPa | 32 |

Bucket diggingforce | kN | 30.1 |

Arm digging force | kN | 19.9 |

Max.traction force | kN | 38 |

Standard | ||

Boom length | mm | 2540 |

Arm length | mm | 1400 |

Bucket capacity | m³ | 0.13 |

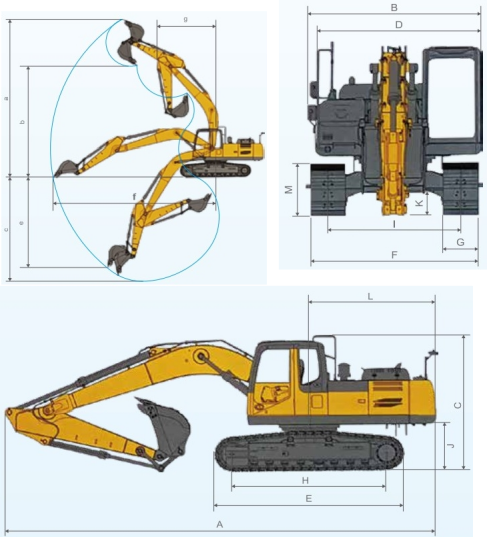

Working Ranges (mm) | |||

a | Max.digging height | 4925 | |

b | Max dumping height | 3475 | |

C | Max.diggingdepth | 3135 | |

e | Max.vertical wall igging depth | 2280 | |

f | Max.digging reach on ground | 5386 | |

g | Min.swing radius | 860 | |

Dimensions(mm) | |||

A | Overall length | 4875 | |

B | Overall width | 1730 | |

C | Overall height | 2550 | |

D | Overallwidthof uperstnucture | 1543 | |

E | Track length | 2122 | |

F | Chassis width | 1730 | |

G | Track shoe width | 300 | |

H | Tracklength on ground | 1640 | |

I | Track gauge | 1430 | |

J | Counterweight clerance | 590 | |

K | Min.ground clearance | 295 | |

L | Min.talsingradius | 860 | |

M | Track height | 524 | |

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.