52-ton Large-Tonnage Crawler Excavator

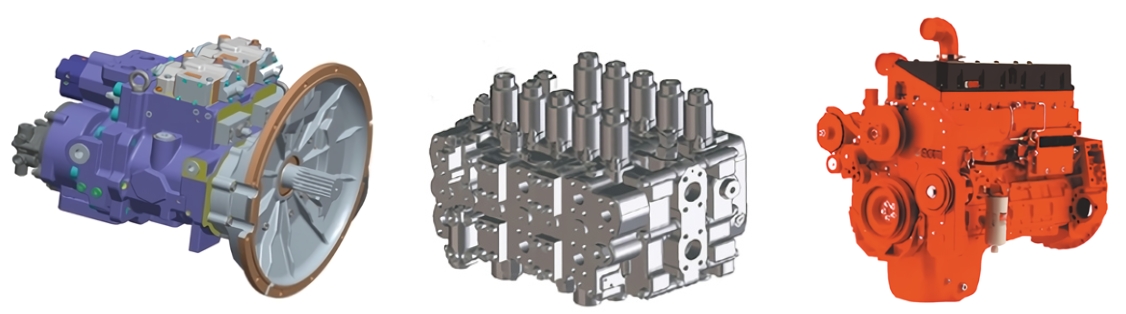

1.Golden Power Combination: Cummins QSM11 engine matched with Kawasaki main pump and Toshiba main valve, achieving perfect synergy between power and control.

2. High-Efficiency and Energy-Saving Benchmark: Electronically controlled fuel injection and high-efficiency hydraulic system, creating core advantages of high efficiency and low fuel consumption.

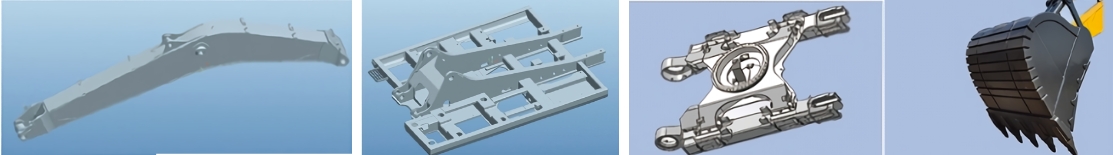

3. Super Strong and Durable Structure: Supported by high-strength steel plates and forged parts, suitable for extreme heavy-duty working conditions.

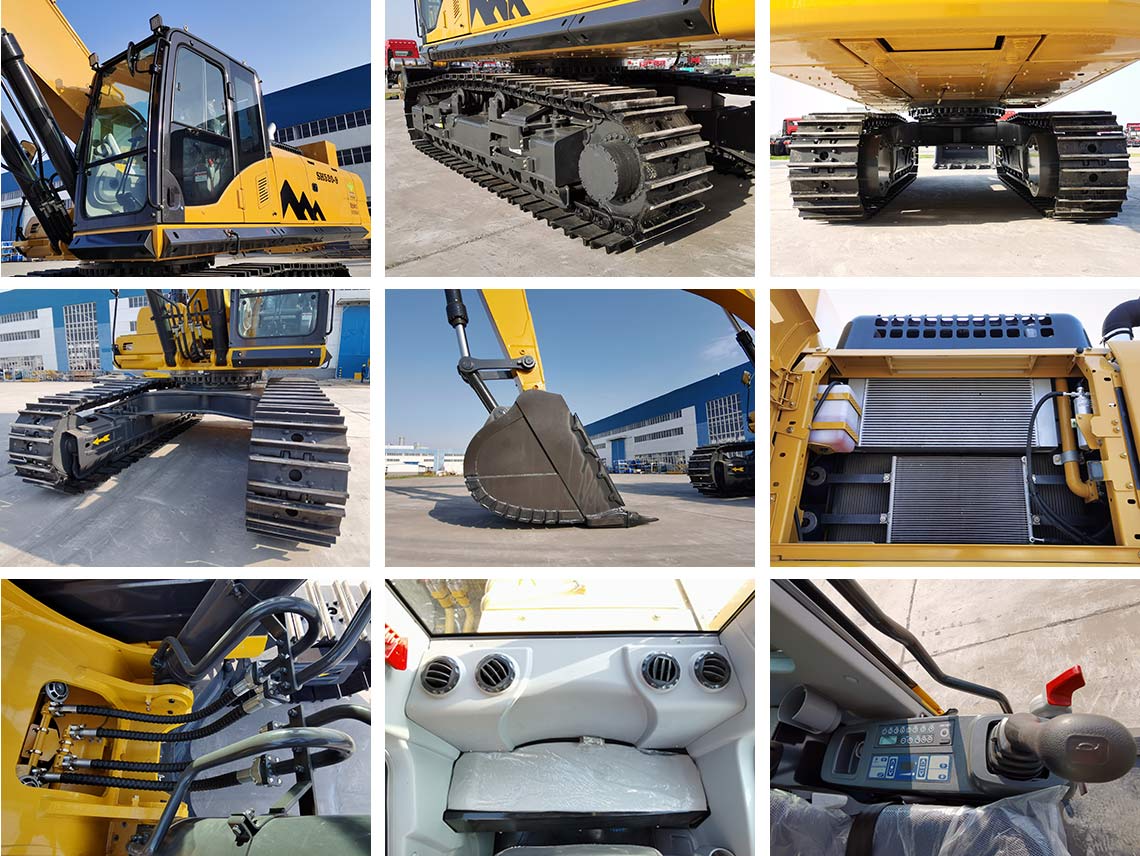

4. Comfortable and Intelligent Operation: Spacious driving space and precise action control, improving operation efficiency and operating experience.

As the newly launched flagship model of Jining Shitian Heavy Industry, the 52-ton large-tonnage crawler excavator has become the preferred equipment for heavy-duty working conditions such as mining and large-scale infrastructure construction, relying on the golden configuration of core components and excellent structural design. Integrating a number of industry-leading technologies, the product accurately matches popular Google search demands such as "crawler excavator", "large-tonnage excavator", and "high-efficiency low-fuel-consumption excavator", providing reliable and efficient construction solutions for global users.

Power Core: Cummins QSM11 Engine, Guarantee of High Efficiency and Low Fuel Consumption

The large-tonnage crawler excavator is equipped with a Cummins QSM11 engine. Relying on electronically controlled high-pressure fuel injection technology, it achieves precise fuel supply, greatly reducing fuel consumption while improving the stability of power output. The engine has core advantages of reliability, high efficiency and low fuel consumption, and can easily cope with complex environments such as high altitudes and high temperatures. It provides continuous and strong power support for the heavy-duty operations of large-tonnage crawler excavators, fully meeting the core needs of global users for high-efficiency and low-fuel-consumption equipment.

Hydraulic Precision Control: Kawasaki Main Pump + Toshiba Main Valve, Precise Response to Heavy-Duty Needs

The hydraulic system adopts the golden combination of Kawasaki main pump and Toshiba main valve. The Kawasaki main pump has significant advantages of high efficiency, high response and large displacement, and also has rich control methods and high power output density. Its high self-priming capacity ensures stable power transmission, and high reliability is suitable for long-term heavy-duty operations. The Toshiba main valve is equipped with multiple intelligent control functions such as straight-line travel circuit, boom priority, swing priority, bucket confluence, boom regeneration technology and arm/boom load holding valve, enabling the large-tonnage crawler excavator to perform precise and coordinated actions in complex operations, greatly improving operation efficiency.

Structure and Operation: Heavy-Duty Optimized Design, Comfortable and Efficient Operation Experience

The crawler excavator excels in structural design. High-stress areas adopt high-strength steel plates, the shaft seat area uses forged parts, and the middle section is welded with a large-section base plate, which greatly improves the load-bearing capacity and durability of the equipment, easily coping with extreme heavy-duty working conditions such as mines. At the same time, it is equipped with a spacious and comfortable driving and operating environment, with an optimized operation layout, effectively reducing the labor intensity of operators. As the flagship large-tonnage crawler excavator of Jining Shitian Heavy Industry, the product has undergone rigorous testing from core components to detailed design, ensuring stable and reliable operation in various heavy-duty scenarios.

With the core advantages of high efficiency and low fuel consumption and the reliable performance of golden configuration, the Jining Shitian SH520-9 large-tonnage crawler excavator injects new vitality into the global heavy-duty construction field and demonstrates the strength of China's construction machinery manufacturing.

Product parameter:

Model | Unit | Parameter |

Engine | ||

Model | Cummins QSM11 | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X125X150 |

Displacement | (L) | 11 |

Rated Power | (kw/rpm) | 280/2000 |

Bucket | ||

Bucket Capacity | (m³) | 2.8-3.0 |

Bucket Width | (mm) | 1968 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 251 |

Bucket Digging Power | (KN) | 292 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2x385+27 |

Traveling Circuit Pressure | (MPa) | 34.3 |

Slewing Circuit Pressure | (MPa) | 28.4 |

System Pressure | (MPa) | 3.9 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x50 | |

Traveling Speed | (km/h) | 3.2/5.3 |

Traction Force | (kN) | 330 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×9 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 50500 |

Ground Specific Pressure | (KPa) | 84 |

Slewing System | ||

Slewing Speed | (r/min) | 9.3 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 650 |

Cooling System | (L) | 39 |

Engine oil volume | (L) | 37.8 |

Hydraulic Tank System Capacity | (L) | 500 |

Bucket type | ||

A Overall Length | (mm) | 12545 |

B Grounding Length (For Transportation) | (mm) | 6733 |

C Overall Height (To Top of Boom) | (mm) | 3590 |

D Overall Width | (mm) | 3490 |

E Overall Height (To Top of Cab) | (mm) | 3286 |

F Counterweight Ground Clearance | (mm) | 1331 |

G Minimum Ground Clearance | (mm) | 696 |

H Tail Swing Radius | (mm) | 4110 |

I Wheelbase | (mm) | 4414 |

J Track Length | (mm) | 5480 |

K Track Spacing | (mm) | 2890/2392 |

L Track Width | (mm) | 3490/2992 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2855 |

P Rotary Table Width | (mm) | 3322 |

Q Distance From Swing Center to Rear End | (mm) | 4110 |

Boom Type | ||

A Maximum Digging Height | (mm) | 11220 |

B Maximum Unloading Height | (mm) | 7814 |

C Maximum Digging Depth | (mm) | 7344 |

D Maximum Vertical Digging Depth | (mm) | 6502 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 7192 |

F Maximum Digging Distance | (mm) | 11774 |

G Maximum Digging Distance at Ground Level | (mm) | 11552 |

H Minimum Turning Radius of Work Unit | (mm) | 4919 |

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.