220-8 Crawler Strong Excavator

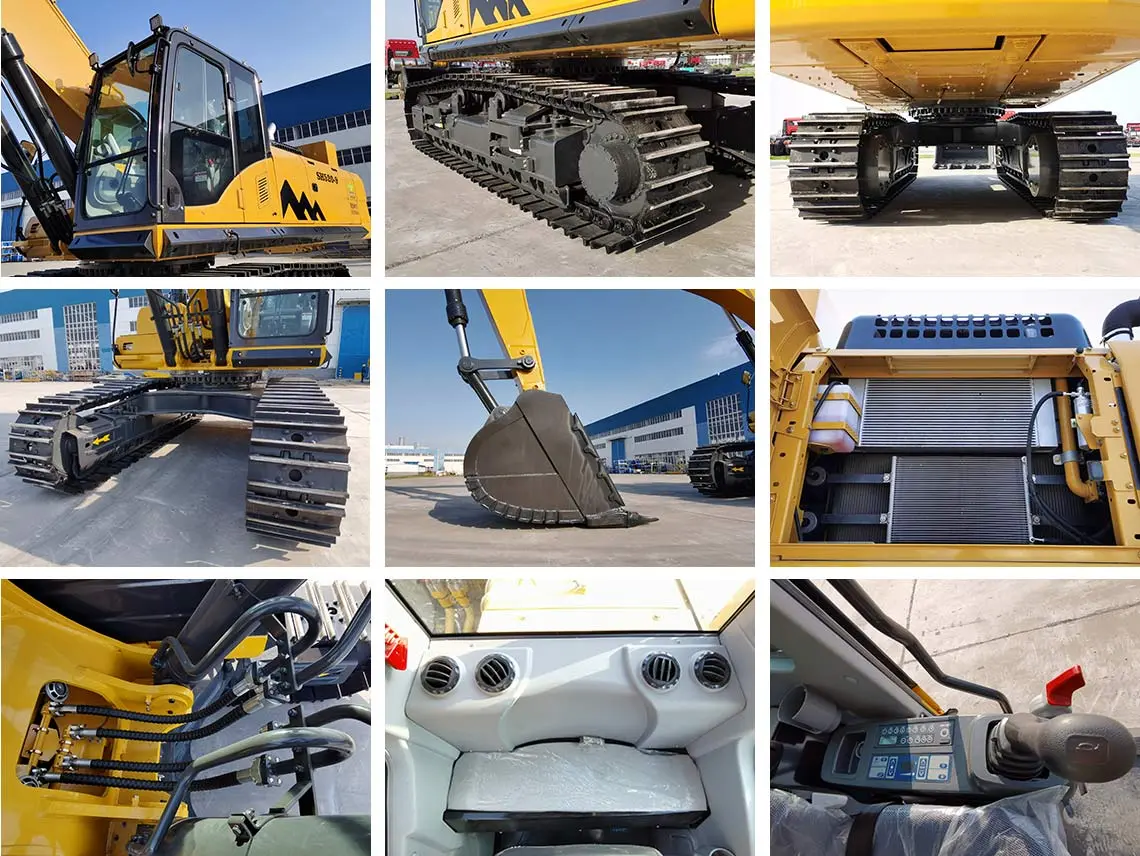

The 220-8 Crawler Strong Excavator is a robust and efficient machine designed for heavy-duty excavation. It features a powerful engine and a durable crawler undercarriage for superior stability and mobility on challenging terrains. Ideal for mining and large-scale construction projects, it delivers high productivity, excellent digging force, and reliable performance in the most demanding working conditions.

Detailed Introduction to the 220-8 Crawler Strong Excavator

The 220-8 Crawler Strong Excavator is a heavy-duty excavation machine designed for extremely harsh working conditions. It integrates superior power performance, a robust structure, advanced control technology, and excellent environmental adaptability, making it an ideal solution for mining, large-scale earthworks, and infrastructure construction projects.

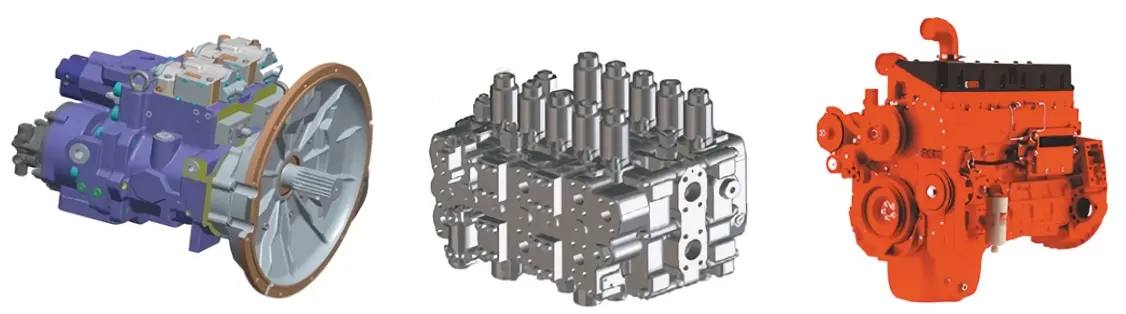

1. Powerful and Efficient Powertrain

At the core of this machine is a high-power, low-consumption turbocharged engine compliant with the latest emission standards. This engine not only provides ample reserve torque, ensuring continuous power during heavy-duty digging and slope climbing, but also utilizes an advanced electronic fuel injection system and intelligent power matching technology. These features adjust the output in real-time based on load demand, achieving an optimal balance between power and fuel economy, effectively reducing long-term operating costs for users.

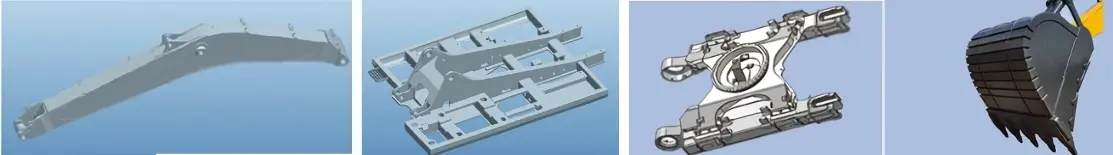

2. Ultra-Durable Structural Design

Its "strength" is reflected in its comprehensive structural reinforcement. Key structural components, such as the boom, arm, and bucket, are manufactured from high-strength alloy steel. Stress concentration areas are fortified with reinforced plate design and robotic welding, significantly enhancing fatigue resistance. The reinforced crawler undercarriage system, featuring widened track shoes, strengthened rollers, and carrier rollers, not only distributes ground pressure to ensure mobility on soft ground but also provides the equipment with unparalleled overall stability and structural durability.

3. Precise and Reliable Hydraulic and Control System

The excavator is equipped with a high-flow negative flow control hydraulic system, which offers swift response and precise control, enabling smooth execution of combined movements and significantly improving operational efficiency. Furthermore, the system's built-in auto-boost mode and multiple power modes (such as Heavy-duty, Standard, and Economy) allow the operator to match optimal performance to different working conditions with a single selection. An advanced Electronic Control Unit (ECU) continuously monitors the machine's status, providing fault warnings and diagnostic information to ensure sustained and reliable operation.

4. Humanized and Safe Operating Environment

The cab, designed according to ergonomic principles, creates a comfortable and quiet operating environment through vibration damping and noise reduction treatments. The panoramic glass windows minimize blind spots. The multi-function suspension seat, intuitive LCD monitor, and ergonomically designed control levers effectively reduce operator fatigue during long working hours. Additionally, the cab complies with Falling Object Protective Structure (FOPS) and Roll-Over Protective Structure (ROPS) safety standards, providing a solid safety guarantee for the operator.

In summary, through meticulous engineering in these four key dimensions, the 220-8 Crawler Strong Excavator ensures that it can deliver stable, efficient, and reliable productivity even in the most demanding operating environments.

Product details:

Company Strength:

Shandong Shitian Heavy Industry Co., Ltd (Jining Shan re-energy) is located in Jining City, Shandong Province, high-tech zone technology industrial development zone. It is a high-tech enterprise specializing in the research, development and production of large excavators. For the large energy-saving excavator design, research and development and production of the leader, the development of hybrid large excavator SH520-9 energy-saving effect reached more than 30%.

In 2020, Jining Shan re-energy hybrid excavator production base project into the key support projects in Shandong Province, its conventional products SH380-9 using a full set of German Linde hydraulic system, strong digging performance, upholding the German industrial products, reliable and efficient design and manufacturing concepts; SH470-9, SH500-9, SH600 in the mines, highways, quarry conditions after decades of verification, known for high efficiency, energy saving The SH470-9, SH500-9, SH600 have been proven in mining, highway and quarry conditions for decades and are famous for high efficiency and energy saving.

Why Choose Us:

The company is equipped with an independent R&D team and collaborates with three large professional teams to carry out product research and development and upgrading work. At present, there are 8 core R&D personnel and 28 professionals in R&D and trial production, providing solid support for technological innovation and product iteration.

In terms of quality control, we fully implement the internationally advanced TQC (Total Quality Control) system, which runs through the entire production process to ensure stable and reliable product quality.

We have formed a team of 21 experienced technical service personnel to provide global customers with comprehensive after-sales service support covering equipment installation, operation training, fault detection, spare parts supply and more.

The production management team has over 15 years of in-depth experience in the construction machinery industry. With a mature management system and rich practical experience, they strictly control every process in the assembly stage to ensure the assembly accuracy and quality of the products.