68-ton Large Hydraulic Crawler Excavator

The 68-ton Large Hydraulic Crawler Excavator is a powerful, efficient, and heavy-duty earthmoving machine. It is engineered to deliver superior digging force and unmatched stability for the most demanding large-scale mining and construction projects. Built with robust components and advanced hydraulics, it guarantees high productivity, remarkable durability, and maximum return on investment in challenging working conditions.

68-ton Large Hydraulic Crawler Excavator: Redefining the Standard for Large-Scale Engineering Operations

As a strategic product in the field of heavy earthmoving machinery, the 68-ton Large Hydraulic Crawler Excavator represents the pinnacle of modern engineering technology. Its design philosophy and performance parameters are all directed toward one core objective: achieving sustained high-efficiency operation under extreme working conditions. This equipment not only meets the rigid demands of large-scale mining and infrastructure construction but also redefines the productivity and durability standards for machinery in this tonnage class through the application of a series of innovative technologies.

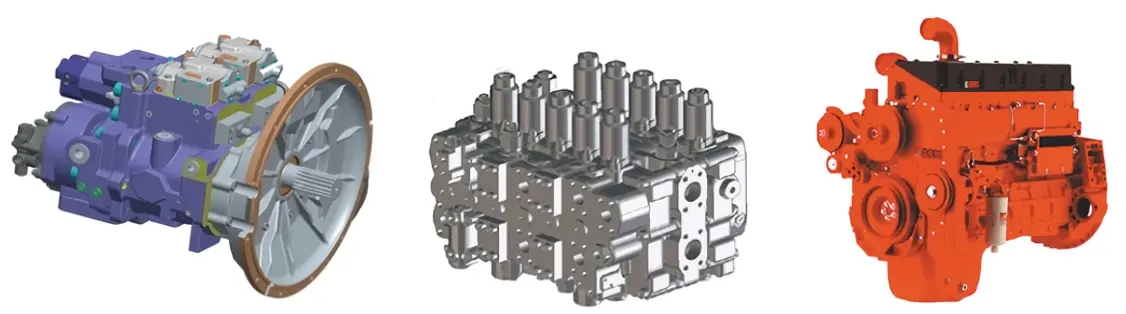

Synergistic Innovation in Power and Hydraulic Systems

The machine is equipped with a high-power-density electronically controlled diesel engine that complies with Tier 4 Final / China IV emission standards. Its rated power reaches 336 kW, with maximum torque exceeding 1,800 N·m. This power core is perfectly matched with a closed-center, load-sensing hydraulic system. The main hydraulic pump utilizes dual-pump merging technology, capable of delivering a hydraulic flow output of up to 2 × 450 L/min. Combined with electro-proportional control valves, it achieves precise fine-tuning of movements and smooth compound actions. The bucket's maximum breakout force reaches 380 kN, and the stick's maximum digging force reaches 290 kN, ensuring efficient excavation and loading capabilities even when dealing with hard rock.

Structural Durability and Operational Stability Design

To cope with immense working loads and impacts, the key structural components of the machine have been comprehensively reinforced. The boom and stick feature box-section design and are manufactured using HG785 high-strength steel, with additional reinforcement plate thickness in stress concentration areas. The track frame employs an X-shaped integrated welded structure, optimized through Finite Element Analysis (FEA), resulting in a approximately 25% increase in torsional stiffness. The standard track shoe width is 600 mm, and the ground pressure is reduced to 120 kPa, providing exceptional ground adaptability and stability, allowing safe operation even on soft dump sites.

Intelligent Management and Maintenance Economics

The integrated intelligent control system is a standout feature of the equipment. It comes with a 10-inch color touchscreen that displays real-time operating parameters and includes functions such as work mode memory, fuel management, and fault self-diagnostics. Furthermore, the CAN bus-based telematics management system allows fleet managers to remotely monitor the equipment's location, working hours, fuel consumption, and maintenance cycles, enabling predictive maintenance.

With centrally located lubrication points, daily lubrication time is reduced by approximately 40%. The replacement intervals for fuel filters and pilot filters are extended to 1,000 hours, effectively reducing the total lifecycle operating costs. Calculations show that in typical mining stripping operations, this equipment can achieve an average annual effective working time of over 6,000 hours, with an availability rate steadily above 95%, providing a solid guarantee for customers' return on investment.

Certificates:

FAQ:

1. Company products and core advantages

Our company has been deeply engaged in the research and development, design and production of a full range of excavators, bulldozers and other construction machinery. At the same time, we have maintained a leading position in the domestic large-scale energy-saving mining machinery and micro-motor industry. The core technical indicators of its mining equipment and microelectronic products have reached the international advanced level, which can precisely match the personalized demands of customers and provide exclusive customized solutions.

2. Payment settlement method

The payment process is as follows: After the contract officially takes effect, the customer needs to prepay 30% of the total order amount as a performance deposit. The remaining 70% of the payment must be settled in full before the goods are dispatched. The shipment will be arranged after the payment is received.

3. Delivery cycle description

The regular delivery cycle is 30 to 45 working days after receiving the deposit. Products in stock can be dispatched immediately. The delivery cycle for customized orders will be adjusted according to specific technical specifications. The final delivery time shall be subject to the confirmation of both parties.

4. Logistics and transportation plan

We offer diversified logistics solutions, covering various transportation modes such as land, sea and air. For different types of equipment, container or bulk cargo transportation methods will be flexibly adopted to ensure the safety and efficiency of goods transportation throughout the process and guarantee the timely delivery of products.