52-ton strong crawler excavator

This is a 52-ton heavy-duty crawler excavator, designed to tackle demanding tasks. With its powerful engine and robust undercarriage structure, it delivers exceptional digging force and operational stability on challenging terrain. It excels in heavy earthmoving, mining operations, and large-scale construction projects, consistently providing efficient and reliable performance to help users overcome the toughest engineering challenges.

52-Ton Heavy-Duty Crawler Excavator

This 52-ton heavy-duty crawler excavator represents the pinnacle of engineering excellence, designed and manufactured to tackle the most demanding and severe working conditions worldwide. It is not merely a machine but a comprehensive solution for large-scale infrastructure construction, resource extraction, and heavy-duty engineering projects, where reliability, power, and efficiency are indispensable prerequisites.

Engine and Powertrain: Unmatched Core Power

At the heart of this excavator lies an advanced, high-torque turbocharged diesel engine that complies with the latest global emission standards (such as EU Stage V or equivalent). The powertrain is meticulously calibrated to deliver exceptional horsepower and immense breakout force, ensuring rapid work cycles and the capability to handle the toughest materials—from fractured rock to dense clay. The advanced hydraulic system incorporates load-sensing variable flow technology, intelligently distributing hydraulic power precisely where and when needed. This not only maximizes operational efficiency but also significantly reduces fuel consumption and effectively manages heat generation, even during prolonged, high-intensity operations.

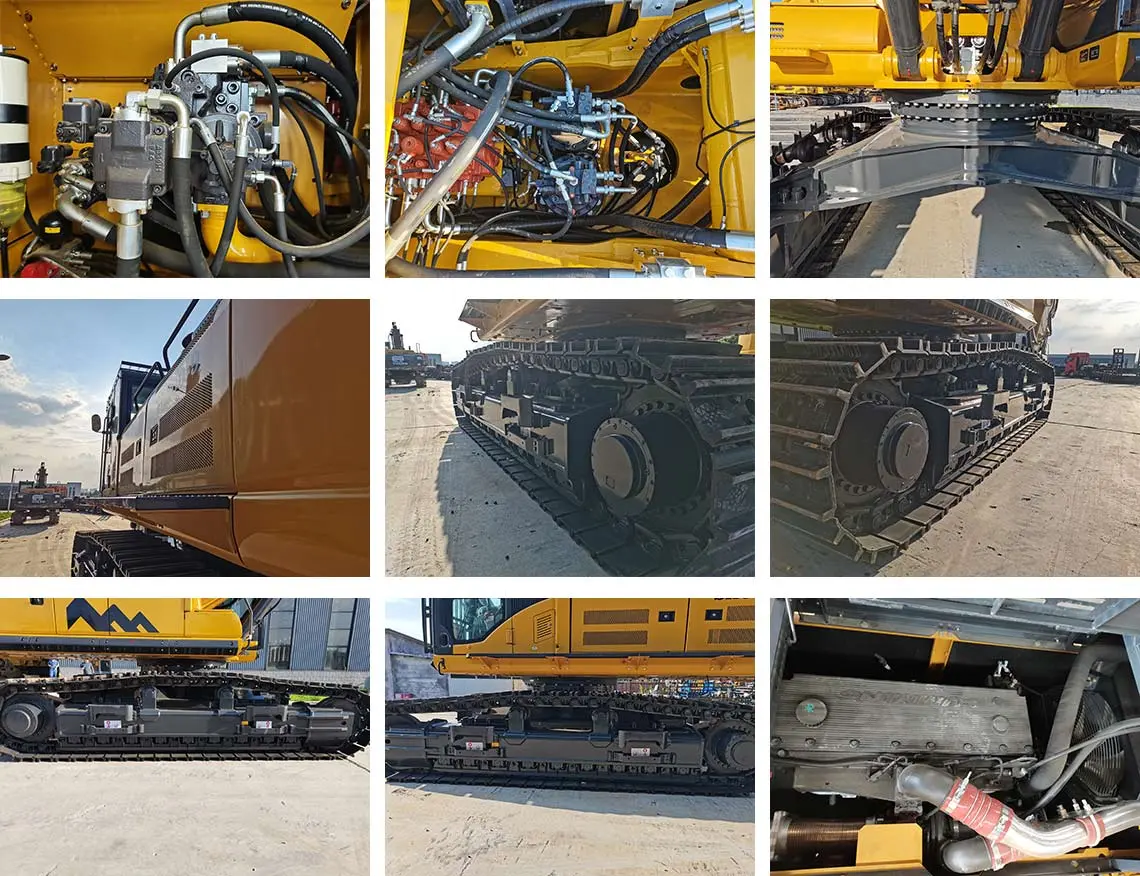

Undercarriage and Structural Integrity: Built for Stability and Durability

The machine’s robustness is anchored by its X-shaped reinforced chassis and heavy-duty crawler undercarriage. The widened track gauge and extended track length provide an exceptionally stable working platform, significantly lowering the machine’s center of gravity and enhancing lifting capacity and safety during swing operations. Key undercarriage components, including rollers, idlers, and sprockets, are manufactured from high-strength, wear-resistant steel, capable of withstanding extreme abrasion and impact loads. This design ensures unparalleled stability and traction across the most challenging and uneven terrains—from soft, muddy sites to steep, unstable slopes.

Exceptional Specialized Application Capabilities

This excavator excels in high-productivity application scenarios:

Heavy Earthmoving: Ideal for large-scale excavation and backfilling operations, demonstrating outstanding performance in quarrying, dam construction, and major road and railway projects.

Mining Operations:With its powerful digging force and rugged structure, it enables continuous overburden removal, shot rock loading, and primary excavation in various mining environments.

Large-Scale Construction Projects: Serving as an indispensable backbone for deep foundation work, port development, and other mega-projects, often operating in tandem with large dump trucks.

Operator-Centric Design and Advanced Technology

The pressurized, sound-dampened cab is designed as a modern command center. It features ergonomic controls, a high-resolution multi-function display, and excellent all-around visibility. Advanced technological interfaces are available as options, including an integrated GPS grade control system for precise excavation and leveling, as well as remote monitoring telematics. These systems provide real-time data on equipment health, location, productivity, and maintenance schedules, enabling fleet managers to optimize utilization, proactively schedule services, and maximize uptime.

In conclusion, this 52-ton heavy-duty crawler excavator is more than just equipment—it is a strategic partner engineered to deliver maximum productivity and reliability. It empowers users to confidently take on the most formidable engineering challenges, ensuring projects are completed safely, on time, and within budget.

Product details:

Why Choose Us:

The company is equipped with an independent R&D team and collaborates with three large professional teams to carry out product research and development and upgrading work. At present, there are 8 core R&D personnel and 28 professionals in R&D and trial production, providing solid support for technological innovation and product iteration.

In terms of quality control, we fully implement the internationally advanced TQC (Total Quality Control) system, which runs through the entire production process to ensure stable and reliable product quality.

We have formed a team of 21 experienced technical service personnel to provide global customers with comprehensive after-sales service support covering equipment installation, operation training, fault detection, spare parts supply and more.

The production management team has over 15 years of in-depth experience in the construction machinery industry. With a mature management system and rich practical experience, they strictly control every process in the assembly stage to ensure the assembly accuracy and quality of the products.