45-Ton Mining Multifunctional Excavator

1.Efficient & Energy-Saving: 8% Fuel Reduction + Low Noise.

2.Strong Power Combination: Cummins Engine + Famous Brand Hydraulic System.

3. Intelligent Operation: Advanced Electronic Hydraulic System & Large-Screen Monitor.

4. Comfortable Driving: Spacious Cab + Humanized Configuration.

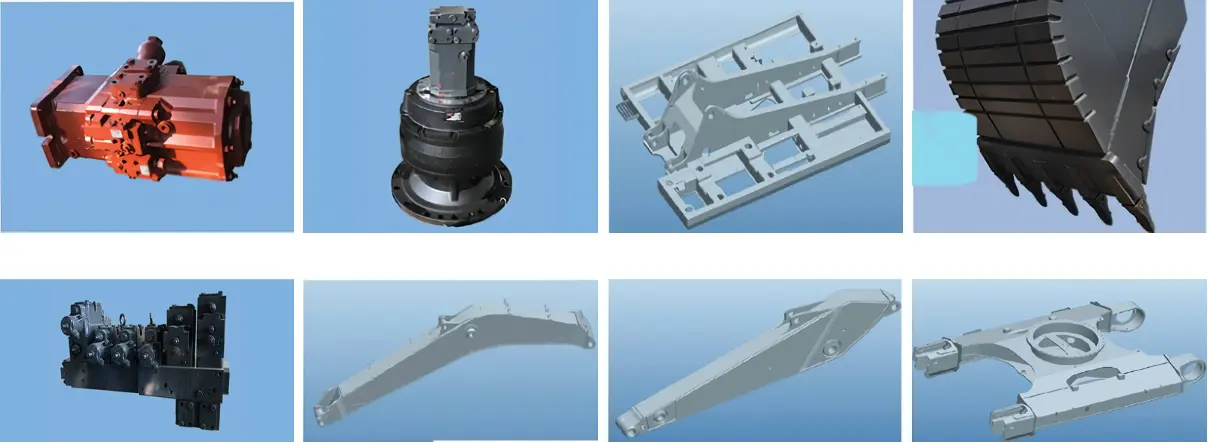

1.Core Power & Hydraulic System, Dual Breakthroughs in Efficiency & Energy Saving

As a high-performance 45-ton large excavator launched by Shandong Shitian Heavy Industry, the SH470-9 is specially designed for medium and large-scale construction scenarios such as mining, road construction and infrastructure projects. Integrating advanced power technology and intelligent control systems, it achieves a perfect balance between operation efficiency, energy conservation and comfort, becoming a reliable choice in the global construction machinery market.

2.Intelligent Monitoring & Maintenance, More Convenient Large-Screen Interaction

The core highlight lies in the optimized power and hydraulic system. Equipped with a Cummins QSM11 high-power engine, the excavator delivers strong and stable power output, ensuring efficient operation even under heavy-load conditions. It is matched with Kawasaki main pump and Toshiba main valve, forming a high-precision and high-reliability hydraulic combination. The advanced electronic hydraulic system not only improves light transmittance and screen resolution, but also provides dynamic images, enabling operators to grasp the working status intuitively. Meanwhile, the adoption of CAN-BUS communication technology realizes comprehensive data collection, laying a foundation for intelligent operation and maintenance. On the premise of ensuring power, the product optimizes the fuel injection mode, reducing fuel consumption by 8% compared with similar products, and effectively lowering working noise, achieving energy saving and environmental protection.

3.Humanized Driving Configuration, New Experience of Comfortable Operation

Intelligent monitoring and maintenance are made easier by the 5.7-inch extra-large color screen monitor. The high-definition screen displays key operating parameters in real time, and the humanized interface design simplifies the operation process, allowing operators to complete equipment monitoring and maintenance reminders with just a glance. This not only reduces the difficulty of daily maintenance, shortens the maintenance time, but also improves the equipment attendance rate. For operators who work for a long time, the excavator is equipped with air-suspension seats as standard. The spacious cab design, low vibration and low noise performance significantly reduce work fatigue. The optional full-automatic air conditioning with multi-directional air outlets can adjust the temperature in the cab in real time, creating a comfortable and convenient working environment for operators.

Shandong Shitian SH470-9 45-ton excavator relies on reliable quality, efficient performance and humanized design to fully meet the diverse needs of medium and large-scale construction. It is a powerful assistant for engineering construction, helping global customers reduce operating costs and improve project efficiency.

Product parameter:

| Model | QSM11 |

| Type | Six-cylinder inline,turbochargin g,intercooling |

| No.of cylinder.Bore and stroke(mm) | 6×125×150 |

| Displacement(L) | 11 |

| Power output(kw/rpm) | 250/2000 |

| Bucket capacity(m3) | 2.0-2.2 |

| Bucket width(mm)(mm) | 1350-1530 |

| Bucket digging force (KN) | 236 |

| Am diging force(KN) | 270 |

| Hydraulic pump form | 2Variable plunger pump+1gear pump |

| Max.discharge flow (L/min) | 2x360+27 |

| Travel circuit(Mpa) | 34.3 |

| Swing circuit(Mpa) | 28.4 |

| Travel motors | Variable axial piston motor |

| Travel shoes | 2×49 |

| Travel speed (km/h) | 5.3/3.2 |

| Drawbar pulling force (KN) | 330 |

| Grade ability | 70%(35°) |

| Support roller quantities | 2×8 |

| Carrier roller quantities | 2×2 |

| Operating weight (Kg) | 44900 |

| Ground pressure(KPa) | 80.2 |

| Swing speed(r/min) | 9.3 |

| Brake | Pressure ReleaseMechanical Braking |

| Fuel tank(L) | 650 |

| Cooling system(L) | 26 |

| Engine oil (L) | 37.8 |

| Hydraulic oil tank /System capacity(L) | 350/450 |

| Overall length(mm) | 12090 |

| Ground Contact Length(Transportation) (mm) | 6723 |

| Overall height (to top of boom)(mm) | 3590 |

| 总宽Overall width(mm) | 3490 |

| Overall height (to top of cab)(mm) | 3276 |

| Counter Weight Ground Clearance(mm) | 1321 |

| Ground clearance(mm) | 557 |

| Tail swing radius(mm) | 3655 |

| Tread(mm) | 4290 |

| Track Length(mm) | 5335 |

| Track Gauge(mm) | 2760 |

| Track width(mm) | 3360 |

| Shoe width(mm) | 600 |

| Bonnet Height(mm) | 2815 |

| Revolving Frame Width(mm) | 3195 |

| distance from swivel center to tail(mm) | 3655 |

| Max.digging height(mm) | 10924 |

| Max.dumping height(mm) | 7615 |

| Max.digging depth(mm) | 7800 |

| Max.vertical digging depth(mm) | 7066 |

| Max.Depth cut for 2440m(8')Level Bottom (mm) | 7650 |

| Max.digging distance(mm) | 12016 |

| Max.digging radius at ground level(mm) | 11814 |

| Min.swing radius of work equipment (mm) | 4825 |

Why Choose Us:

1. We have an independent R&D team and cooperate with 3 large collaborative teams to develop and upgrade products. There are 8 core R&D members and 28 R&D and trial production staff.

2. Utilizing the international advanced TQc total quality management system to implement quality control management.

3. 21 senior technical service personnel to provide a full range of after-sales service.

4. Advanced production management team, industry management experience of more than 15 years, to ensure the assembly quality.