38 T High-Efficiency Hydraulic Excavator

1.Genuine Isuzu 6HKIX engine, powerful heavy-load performance with low consumption & durability;

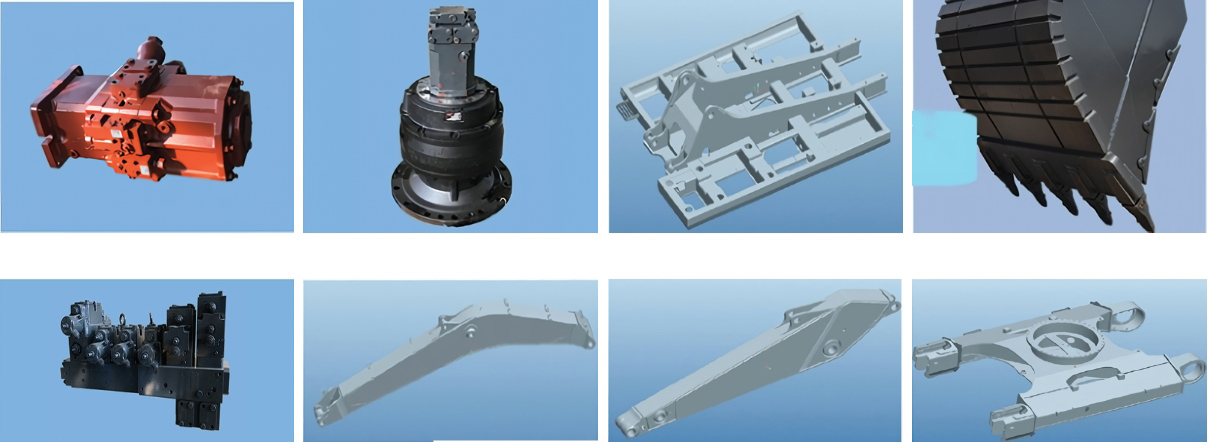

2.Full set of German Linde hydraulic system, precise, efficient & high-stability;

3.National III compliant for wide adaptability, seamless continuous operation under high-intensity conditions.

Product Background

The global excavator market is stepping into a new phase of technological innovation and refined segmentation of application scenarios. By the end of 2025, the global market size exceeded 115 billion US dollars. Large-sized excavators (below 40 tons) account for 15.7% and maintain strong demand due to their adaptability to heavy-load scenarios such as mining and large-scale infrastructure. Infrastructure booms in emerging markets of Asia-Pacific, Africa and Latin America, along with the upgrading demand for existing heavy-load equipment in Europe and the United States, have made 38-ton large-sized crawler excavators a rigid demand category. International buyers focus on genuine core component quality, heavy-load stability and compliance. With dual genuine core configurations of Isuzu and Linde, this product accurately addresses industry pain points and maintains leading competitiveness in the segment market.

Isuzu Power Core: Building the Foundation for Heavy-Load Performance

The 38-ton large-sized crawler excavator is equipped with a genuine imported Isuzu 6HKIX six-cylinder engine, the golden power core for heavy-load engineering equipment. Its 7.8L large displacement can deliver 184kW rated power and 883N·m peak torque, with heavy-load explosive power and continuous output capacity far exceeding peers, easily handling high-intensity operation scenarios such as mine hard rock excavation and large-scale earthwork transportation. Adopting mature closed-loop combustion control technology, the engine strictly complies with National III emission standards, which can be adapted to most emerging global markets and engineering scenarios without additional modification. It also has excellent wear resistance and high-temperature resistance, with a failure rate 40% lower than similar engines, significantly reducing long-term operation and maintenance costs and downtime losses.

German Linde Hydraulic System: Empowering Precise Heavy-Load Operation

The equipment is equipped with a full set of genuine imported German Linde hydraulic system, integrating Linde load-sensing pump and Linde swing motor to form a top-tier hydraulic transmission closed loop, which is the core guarantee for the accuracy and stability of heavy-load operations. The Linde load-sensing pump can achieve millisecond-level load response, intelligently adjust flow output, with pressure loss 20% lower than ordinary hydraulic pumps, ensuring sufficient output of heavy-load digging force while maintaining operation smoothness and avoiding impact damage. The Linde swing motor adopts enhanced sealing and braking design, with stable start-stop without jitter and reliable braking without sliding, performing excellently in high-precision scenarios such as heavy-load swing and fixed-point excavation. The entire system is deeply matched with the Isuzu engine, with a power transmission efficiency of up to 92%, improving heavy-load operation efficiency by more than 18% compared with peer products, and extending the service life of hydraulic components by 30% compared with the industry average, adapting to various heavy-load scenarios such as mining, large-scale infrastructure and port loading and unloading.

Genuine Core Configuration: Meeting Global Heavy-Load Demands

Relying on the synergistic advantages of dual genuine core configurations of Isuzu and Linde, the equipment not only strictly complies with National III emission standards, adapting to environmental regulations of most emerging global markets and some mature markets, but also forms an absolute advantage in heavy-load reliability and total life cycle cost control. High-strength wear-resistant steel is used in the manufacturing process to build the body and working device. Combined with the precision craftsmanship of the Linde hydraulic system and the stable performance of the Isuzu engine, the overall failure rate under heavy-load conditions is 35% lower than the industry average, significantly improving operation continuity and reducing project delay losses caused by downtime. When purchasing large-sized excavators, international buyers' core pain points focus on the authenticity of genuine components, heavy-load stability and after-sales support. With dual genuine brand endorsements, a global component supply system and joint after-sales support, this product solves procurement concerns from the source, with a total life cycle cost 25% lower than similar products.

Product parameters:

Model | Unit | Parameter |

Engine | ||

Model | Isuzu 6HKIX | |

Form | 6-cylinder, inline, supercharged, intercooled | |

Cylinder X Bore X Stroke | (mm) | 6X115X125 |

Displacement | (L) | 7.79 |

Rated Power | (kw/rpm) | 212/2000 |

Bucket | ||

Bucket Capacity | (m³) | 1.62-1.82 |

Bucket Width | (mm) | 1571 |

Digging Power | ||

Bucket Lever Digging Power | (KN) | 190 |

Bucket Digging Power | (KN) | 230 |

Hydraulic System | ||

Hydraulic Pump Type | 2 variable piston pumps + 1 gear pump | |

Maximum Flow Rate | (L/min) | 2×330 |

Traveling Circuit Pressure | (MPa) | 36 |

Slewing Circuit Pressure | (MPa) | 25.5 |

System Pressure | (MPa) | 36 |

Walking System | ||

Traveling Motor | Axial Variable Piston Motors | |

Number of Track Plates | 2x49 | |

Traveling Speed | (km/h) | 5.0/3.0 |

Traction Force | (kN) | 280 |

Climbing Capacity | 70%(35°) | |

Number of Supporting Wheels | 2×8 | |

Number of Sprocket Wheels | 2×2 | |

Operating Weight and Ground Specific Pressure | ||

Operating Weight | (Kg) | 37000 |

Ground Specific Pressure | (KPa) | 62 |

Slewing System | ||

Slewing Speed | (r/min) | 9.7 |

Brake Type | Pressure relief, mechanical brake | |

Oil Capacity | ||

Fuel tank capacity | (L) | 580 |

Cooling System | (L) | 32.5 |

Engine oil volume | (L) | 33 |

Hydraulic tank filling volume/hydraulic system capacity | (L) | 380/450 |

Bucket Type | ||

A Overall Length | (mm) | 11161 |

B Grounding Length (For Transportation) | (mm) | 5872 |

C Overall Height (To Top of Boom) | (mm) | 3347 |

D Overall Width | (mm) | 3200 |

E Overall Height (To Top of Cab) | (mm) | 3293 |

F Counterweight Ground Clearance | (mm) | 1312 |

G Minimum Ground Clearance | (mm) | 565 |

H Tail Swing Radius | (mm) | 3438 |

I Wheelbase | (mm) | 4080 |

J Track Length | (mm) | 5044 |

K Track Spacing | (mm) | 2600 |

L Track Width | (mm) | 3200 |

M Track Plate Width | (mm) | 600 |

O Hood Height | (mm) | 2421 |

P Rotary Table Width | (mm) | 3195.3 |

Q Distance From Swing Center to Rear End | (mm) | 3438 |

Boom Type | ||

A Maximum Digging Height | (mm) | 10134 |

B Maximum Unloading Height | (mm) | 7182 |

C Maximum Digging Depth | (mm) | 7240 |

D Maximum Vertical Digging Depth | (mm) | 7170.5 |

E Maximum Digging Depth When Digging Out 8 Feet of Horizontal Surface | (mm) | 6812.5 |

F Maximum Digging Distance | (mm) | 11051 |

G Maximum Digging Distance at Ground Level | (mm) | 10839 |

H Minimum Turning Radius of Work Unit | (mm) | 4332 |

As a mainstream category of large-sized excavators, the 38-ton crawler excavator is widely used in heavy-load fields such as mining, large-scale highway and railway infrastructure, and port terminal construction, especially suitable for large-scale infrastructure expansion needs of countries along the "Belt and Road". With the increase of global large-scale engineering construction projects, the market penetration rate of heavy-load excavators with genuine core component configurations continues to rise. Relying on the powerful durability of Isuzu power and the precision efficiency of Linde hydraulics, this product forms a differentiated competitive advantage among peer products, becoming the preferred equipment for international mining enterprises and large-scale engineering contractors to reduce operating costs and improve construction efficiency.

FAQ

Does the excavator support customization to adapt to emission standards in specific regions?

We can customize and adjust engine emission parameters according to target market needs, adapt to environmental regulations of different countries and regions, and provide compliance certification documents.

What is the global after-sales support for Isuzu 6HKIX engine and Linde hydraulic system?

Relying on the global service networks of Isuzu and Linde, we provide genuine parts supply and professional on-site maintenance services in more than 120 countries, with an average response time of no more than 72 hours, and priority maintenance support under heavy-load conditions.